DCT250 PowerShift Transmission — information about rebuild (MPS6)

Repair Ford PowerShift DCT250 DPS6/MPS6 should be performed only by the specialists with the use of original spare parts. Owners of the Ford Focus 3 are familiar with the 6-speed PowerShift 6DCT250 transmission with a dual dry clutch. These transmissions were intended for small-volume engines of urban cars, but such transmissions were not too durable on powerful cars, so major rebuild of transmission Powershift DCT250 could be required already on a run of 150 thousand. The robotic transmission causes conflicting reviews from owners and masters of car service stations.

Such transmissions were distinguished by a complex design, so even today, they haven’t received the proper distribution, being installed on separate cars of European brands.

Japanese gearboxes «MPS6” are structurally different from the German robotic machine, but separate consumables are interchangeable. In Japan, such transmissions have not received proper distribution, since local car manufacturers still prefer to use classic automatic machines or variators rather than robots with a complex design.

PowerShift DCT250 Problems

The electronic part of the robotic transmission cannot boast of the same reliability as the mechanics. The troubles with it can occur after the first 25-30 thousand km of mileage. Most owners of Ford Focus cars have problems starting with periodic jerks when driving. Many drivers will consider this a structural flaw in the robot, but in reality, it is a malfunction that requires immediate rebuild PowerShift DCT250.

Due to the electronic part, it is difficult to call it reliable and durable. The weak points of this transmission are the TCM and the clutch.

If you want to make the robot box switch correctly, you need to repair PowerShift DCT250 twice a year at a car service.

Teardown DCT250 PowerShift GETRAG

Another common reason for contacting the service is to rebuild Ford PowerShift DCT250 combustion because of the dirty oil of the frictions, which are replaced as a set. As for the iron part, when performing a major overhaul, the clutch basket, springs and retainers are replaced. Steel wheels, sets of rubberized pistons, multi-plate clutch, and other iron are ordered for a bulkhead of the transmission. During each opening of this machine, all seals are replaced to avoid the oil leakage, since any pressure drop in the system will be detrimental to this machine.

DCT250 TCM Module

[ads1]

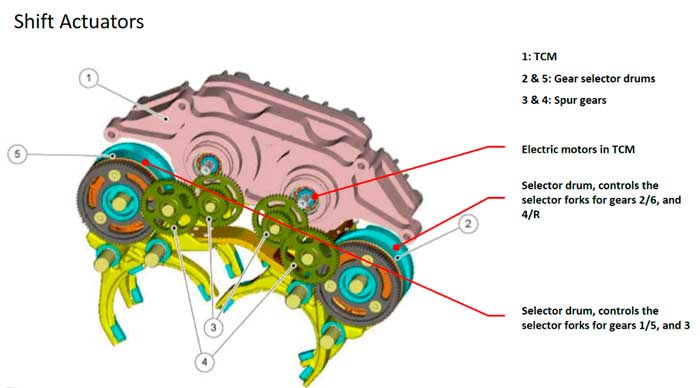

The TCM is a transmission control unit. It consists of electric motors that turn on and off the clutches and an electronic board that regulates these processes. Comparing with cars with the manual transmission, where the driver decides when and how fast to squeeze the clutch, in a robotic transmission, these functions are taken over by the electronic unit.

Problems with the TCM usually begin with periodic jerks when moving. If you turn off the engine and then start it again, the problem will temporarily disappear. But this does not mean that the transmission is all right, and it does not need repair. The main signs of failure of the TCM:

- jerks when driving, jerks when changing gears;

- no gear indication;

- failure of the rear transmission;

- problems when choosing a sports mode;

- bad traction;

- unable to start the engine.

Problems with MPS6 clutch

[ads1]

PowerShift DCT250 transmission is hardly a reliable and durable gearbox. Due to proper operation and timely maintenance, the robotic transmission will please its owner with instant gear changes and low fuel consumption for a long time.

Problems with this node occur less often than with the electronic control unit, but such failure is also not uncommon. The fork or release bearing most often goes down.

PowerShift DCT250 Clutch Replacement Video

PowerShift often has a jammed clutch fork. In most cases, trouble occurs in both parts. In this case, the gearshift is also disrupted. The problem is that odd speeds may not work, or all gears may not switch at once.

If you want to extend the service life of the transmission, you need to change the oil regularly. Although the manufacturer claims that this box is maintenance-free, but experience shows that changing the oil can significantly extend the service life of the unit.

Features of Ford PowerShift DCT250

[ads1]

The robotic transmission combines the properties of mechanics and automatics. The mechanical part includes conventional gears and two clutches. DPS6 Transmission has two primary shafts that are responsible for even and odd gears. This allows you to quickly switch and adapt to the driving style of a particular driver.

This made it possible to switch speeds more smoothly, significantly reduce the vibration level, and get rid of third-party sounds. Thanks to the use of cast parts, the mechanical part of the robotic transmission is highly reliable. The electronic vehicle control unit is responsible for shifting gears. The clutch is powered by an electric motor.

DCT250 (Ford Focus, Fiesta) TCM Failure Symptoms

PowerShift DCT250 has a dry grip. This means that the transmission does not have its own cooling system. If you drive aggressively for a long time, the unit may overheat, and this transmission is not intended for sports driving.

Fluid change in Ford PowerShift DCT250

One of the prerequisites for the trouble-free operation of such a robotic gearbox is to keep oil clean. Transmission service, fluid replacement must be carried out every 120.000 km.

The car manufacturer recommends using a special oil for robotic gearboxes “BO-DC”. The recommended type and class of transmission fluid may vary depending on the manufacturer.

PowerShift DCT250 actuators TCM

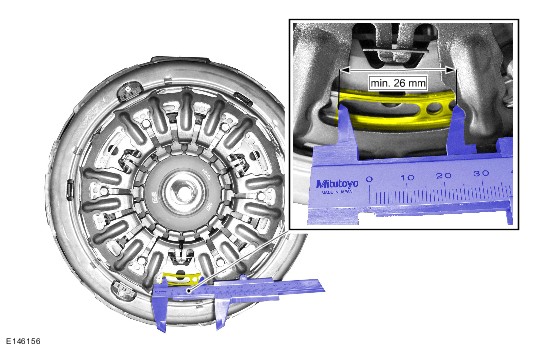

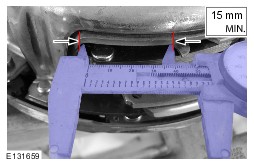

Powershift DCT250 MPS6 Clutch replacement manual

[ads1]

DOWNLOAD DCT250 DPS6 MPS6 Manuals pdf free

[ads1] |